4 Key Environmental Sustainability Topics In The Manufacturing Sector

What is the first thing that comes to mind when talking about environmental sustainability in the workplace? Many of us will probably think about improving daily office activities, such as reducing plastic use and waste recycling.

Despite the saying that small things can make a big difference, this is just the tip of the iceberg. Even more so in the manufacturing sector, which is the second-highest greenhouse gas (GHG) emitting industry after oil, gas and energy.

84% of Europeans believe that sustainability should be embedded at the core of business activities. Similarly, 73% of Americans wouldn’t purchase from a company that doesn’t consider climate change in its business practices.

As organisational change cannot be achieved without the full participation of employees, this article breaks down 4 key environmental topics for the manufacturing sector.

Is sustainable manufacturing the only way forward?

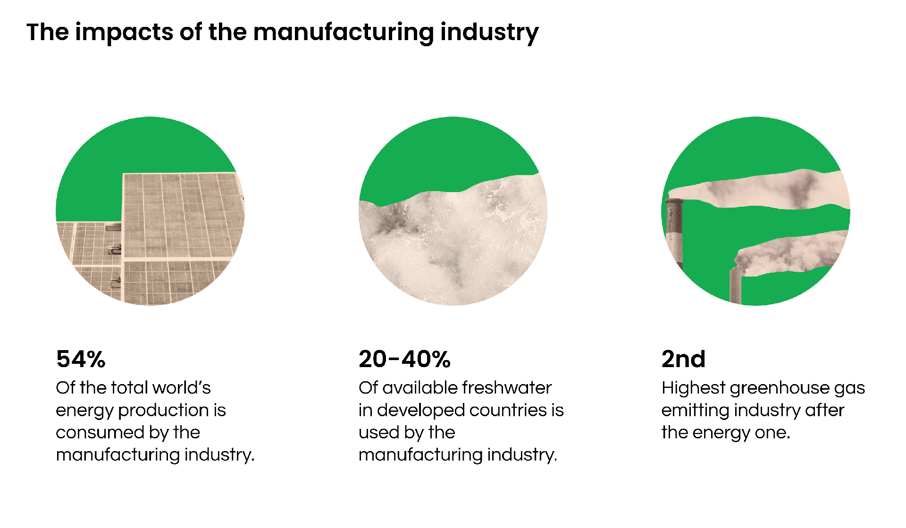

The manufacturing industry has a major impact on our planet:

- It consumes 54% of the total world's energy production;

- It utilises between 20% to 40% of available freshwater in developed countries;

- In 2020, the European manufacturing sector generated approximately 880 million metric tons of CO2. This number grows to 1,435 million metric tons with respect to the US industrial sector.

To put this into perspective, a million metric tons corresponds to the mass of a million small cars.

Hence, to tackle the current environmental crisis, the concept of sustainable manufacturing becomes crucial.

According to the US Department of Commerce:

“Sustainable manufacturing is the creation of manufactured products that use processes that minimize negative environmental impacts, conserve energy and natural resources, are safe for employees, communities, and consumers, and are economically sound.”

What trends are shaping the manufacturing industry?

From designing sustainable products to improving supply chain practices, key sustainability trends in manufacturing include:

Net-Zero Strategy

Companies are embarking on the net-zero journey to curb their emissions and exploit the massive business opportunities stemming from it. In fact, according to McKinsey, the net-zero transition could generate more than $12 trillion in annual sales by 2030.

Data & Technology

Research shows that 60% of businesses with strong digital capabilities are prioritising sustainability in their operations. In fact, these companies are developing sustainability practices based on data. For example, optimised production processes to reduce scraps and increase circularity.

Moreover, technology and AI are proving to be powerful in the:

- Reduction of emissions;

- Improvement of energy efficiency;

- Increase in the use of renewable energy.

According to 87% of the interviewed CEOs for the 2022 BCG Climate AI Survey Report, AI can be a crucial tool to halt climate change.

Biodiversity

More and more companies are including nature conservation and biodiversity protection initiatives in their climate strategies. We go into more detail on biodiversity in this article.

Disclosure

A growing number of companies are disclosing their impacts on people and the planet through sustainability reporting standards.

This trend fits in with both new regulations and laws concerning business transparency, accountability and stakeholder pressure.

Coopetition

Finally, businesses in the manufacturing industry are partnering up to achieve their sustainability ambitions.

For example, Cartier and Kering launched the Watch & Jewellery Initiative 2030 to build climate resilience, preserve resources, and foster inclusiveness.

Which sustainability topics should your employees master?

The four key environmental topics for manufacturing covered in this article are:

- Sustainable Manufacturing Legislation

- Sustainability Assessment Tools & Techniques

- Carbon Footprinting

- Sustainability Reporting

Before we get started, it is important to understand how employees' expertise changes depending on roles and responsibilities.

Production workers should be trained to use the appropriate equipment and feed relevant information into dedicated forms, software, or apps.

Middle management knowledge should revolve around product design, procurement practices, and research & development (R&D) to cut carbon emissions.

Finally, executives should be well-versed in utilising carbon footprint knowledge in decision-making and risk management.

1. Sustainable Manufacturing Legislation

In light of the numerous laws and regulations developed, companies in the manufacturing sector should jump on the sustainability wagon to future-proof their business.

To name a few of the ones your employees should be familiar with, we can cite:

- Programme For The Environment & Climate Action (LIFE) (2021-2027)

- European Climate Law

- Corporate Sustainability Reporting Directive (CSRD)

- 8th Environment Action Plan to 2030

It's important for employees at different levels to understand upcoming legislation, the importance of compliance and the impact it has on your organisation.

2. Sustainability Assessment Tools & Techniques

There are different tools and techniques your employees can use to quantify the company's current impact, such as:

- ESG Assessment & Ratings;

- Life Cycle Assessment.

ESG Assessment and Ratings

ESG Assessments & Ratings are used to measure a company's impact through an evaluation of its environmental footprint, social relationship, and governance.

Conducting an ESG Assessment plays a big role in attracting investments. As of 2019, the sustainable investment market has crossed $30 trillion.

Across the most used ESG Assessments and Ratings, we can mention:

- S&P Global ESG Ratings

- EcoVadis

- CDP Scores

- Dow Jones Sustainability Indexes

Life Cycle Assessment

A Life Cycle Assessment consists of quantifying the environmental impacts of a product or process throughout its entire life cycle. This means including all the impacts that occurred from raw materials extraction to final disposal.

Conducting an LCA will help you identify where the biggest impacts occur. Based on that, actions can be taken to reduce negative effects.

Breaking down silos when it comes to going through these exercises will improve employee engagement and increase awareness of the relevant sustainability topics.

3. Carbon Footprinting

Measuring the carbon footprint of your organisation is the first step of a decarbonisation strategy. In fact, it allows you to understand where you currently are and act accordingly.

The main landmark in carbon footprinting is the GHG Protocol, which categorises climate impact into three scopes:

- Scope 1: it refers to all those GHGs directly emitted by the organisation in the conduct of its business activity.

- Scope 2: it includes indirect sources of emissions, such as purchased electricity, steam, heating, and cooling.

- Scope 3: this is responsible for up to 90% of the overall carbon emissions of a company. It encompasses all other indirect emissions that occur throughout the value chain, both upstream and downstream.

Download our factsheet to understand environmental footprints in more detail

Based on the GHG Protocol, carbon accounting is articulated in 5 main steps:

- Step 1 – Understand the scopes and organisational boundaries;

- Step 2 – Collect activity data from different internal and external sources;

- Step 3 – Convert the activity metrics into carbon emissions;

- Step 4 – Determine which framework to use and calculate Scope 1, 2, and 3;

- Step 5 – Report emissions and disclose goals and targets.

4. Sustainability Reporting

Through sustainability reporting, an organisation communicates its sustainability progress to stakeholders.

Some of the widely used reporting standards and frameworks are:

- Global Reporting Initiative (GRI)

- Sustainability Accounting Standards Board (SASB)

- Task Force on Climate-Related Financial Disclosures (TCFD)

- The upcoming Corporate Sustainability Reporting Directive (CSRD)

Additionally, some of these international standards, such as the GRI are developing sector-specific guidelines based on the high-impact areas of each industry.

How to educate employees on these topics?

The best way to educate your workforce on sustainability matters is through tailored sustainability training.

First of all, make sure that the basics of sustainability are understood throughout the entire organisation to guarantee engagement and motivation.

Secondly, structure training content in relation to the roles and responsibilities of employees, as mentioned above.

In practical terms, training can be provided through different formats:

- In-house training programmes, based on the specific needs of the organisation. This option gives you full control over the content covered in the training. However, it can be quite time-consuming. This is particularly true in the field of sustainability, where news and developments are constant, thus implying the need for frequent revision and updates.

- External online sustainability courses can be a quick way to upskill your employees. However, they often can't cover the exact needs of your organisation and tend to lack a human touch.

- Outsourced trainers, such as consultants and sustainability experts. They can tailor the content based on your needs and guide you on the sustainability journey.

Create awareness on sustainability topics at every level

All in all, make sure your entire workforce is aware and engaged with the sustainability ambitions of the organisation.

- Workers in the production lines should have a high-level understanding of the impacts generated through the production process and of how to reduce them.

- Middle management should have a deeper knowledge of sustainability issues

- C-suite needs a solid grip on these topics to achieve the company's sustainability goals, choose investments, and reduce risks.

Research shows that 70% of employees involved in sustainability initiatives felt stronger loyalty to their company. Training your workforce on sustainability matters is a win-win for your company as well as the planet.