4 Practical Steps to Implement ISO20400

With up to 90% of GHG emissions coming from organisations' supply chains, procurement should probably be in the top 3 things to think of in relation to sustainability.

You may also have seen recent reports uncovering supply chain scandals. Big companies tend to have large and complex value chains. More often than they should, they contain unsustainable working conditions.

ISO 20400 is the international standard for sustainable procurement. It provides guidance to organizations on integrating sustainability within procurement’s strategy and actions.

What is sustainable procurement?

“Sustainable procurement is procurement that has the most positive environmental, social and economic impacts possible across the entire life cycle and that strives to minimize adverse impacts.” ISO20400 International Standard

Introducing a sustainable procurement program can be the answer to many of the problems that businesses are currently experiencing:

- It offers a competitive advantage: companies are able to respond to stakeholder expectations and foster more innovation through supply chain collaboration;

- It helps build a strong relationship with suppliers, resulting in more commitment from their side;

- It helps companies focus on environmental and social actions;

- It helps avoid supply chain and reputational risks associated with suppliers’ bad practices.

You may be thinking that this sounds great, but how do you go about implementing it?

4 steps to implement supply chain management (SCM)

.png?width=3762&name=Figure%201.%20Steps%20to%20implement%20a%20Sustainable%20Procurement%20MS%20(1).png)

Step 1 – At the strategy level

According to the ISO20400 sustainable procurement standard, the first step is for management to fully commit. To integrate sustainability into the procurement strategy an official mandate needs to be given to the right people. For large and extra-large companies, the head of procurement is accountable for carrying out the strategy.

On top of that, sustainability is integrated into the teams’ objectives and job descriptions. For small and medium companies, the owner or manager, in the absence of a distinct procurement team/manager, will be accountable. Integrating sustainability at this level will guide current and future procurement decisions. Supply chain performance is directly linked to that of the team.

The next step is to implement and review the policy and the strategy.

A policy expresses the procurement intentions, objectives and values. The document should take into account environmental, social and economic considerations and address the principles of sustainable procurement. For example, the policy can include the company’s commitment to not work with suppliers whose operations are not compliant. They can require companies to respect local and international standards on labour conditions and environmental practices.

A (sustainability) strategy is a written plan that outlines the key objectives and targets for sustainable procurement. It also presents a basic work plan. Setting goals comes from a clear overview of the procurement practices in place and the supply chain.

To understand the supply chain the company should take into consideration:

- The core management processes;

- The complexity and number of tiers;

- Transparency within the supply chain;

- Important actors and partners;

- External influences and sustainability impacts.

Step 2 – At the people level

As always, stakeholders play an important part in the success of a strategy. Engaging with both internal and external stakeholders is fundamental.

Internally, management is responsible for identifying the learning needs and ensuring employees have access to the training and support needed. In addition, sustainability should be integrated into performance reviews and/or incentive plans. Intel, for example, has aligned short-term incentives with ESG metrics (including diversity, inclusion, employee experience, climate change and water stewardship).

Including ESG metrics into short and long-term incentives is a great way to motivate people toward sustainability. Companies interested in implementing it should first select the relevant performance measures. We advise establishing a correlation between the success rate and the incentives given.

Externally, stakeholders should be engaged in activities that go beyond contractual requirements. Such activities allow the companies to build a stronger collaboration with stakeholders and seek opportunities for collaboration. Good examples of engagement techniques are industry sustainability initiatives, supplier development plans, capacity-building programs and supplier diversity initiatives.

For example, the Responsible Beauty Initiative was founded by L’Oréal, Groupe Rocher, Clarins and Coty in 2017. Together, the organisations aim to improve sustainability throughout the entire beauty supply chain. The goal is for companies to collaborate to accomplish more together and boost sustainability in the value chain.

LC Packaging is part of the Plastic Pact Netherlands a joint initiative between various packaging companies. With the pact, companies committed to moving towards a circular approach. They ensure all final products can be recycled, eliminating unnecessary plastic packaging and using recycled and biobased plastics.

Henkel has launched a Supplier Diversity Program to provide opportunities for certified diverse suppliers to do business with the company. Diverse means including disabled, minority, veteran and women-owned businesses.

Step 3 – At the operational level

Of course, organisations cannot do everything at once. In order to manage the priorities, we recommend:

- Identifying short-, medium- and long-term risks;

- Assessing their criticality;

- Implementing the necessary activities to reduce risks;

- Seeking opportunities.

This order of actions will be the priority for the procurement team.

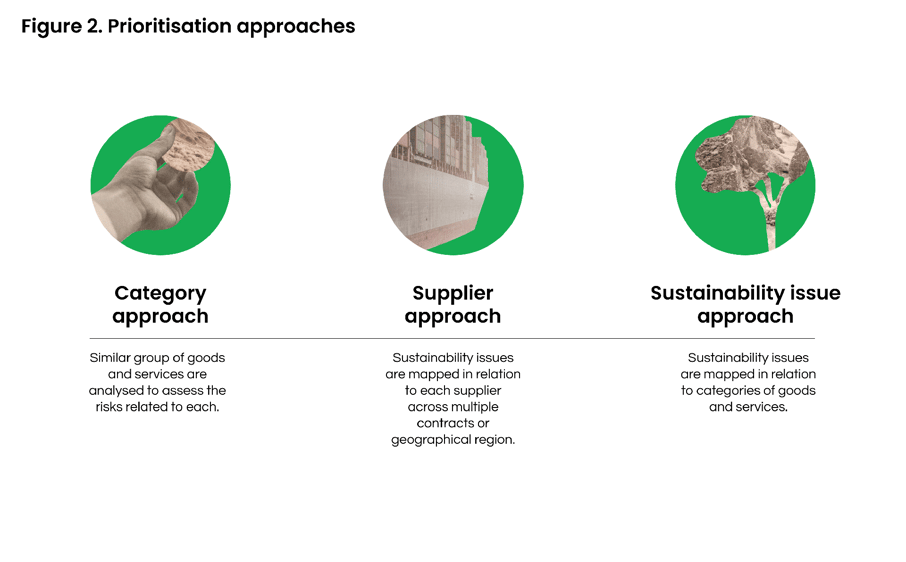

Companies can choose between a category approach, a supplier approach or a sustainability issue approach.

In the category approach, similar groups of goods and services are analysed to assess the risks related to each. Relevant factors include the purchase volume, criticality to the operations, country context and future operational requirements. The categories taken into consideration can include, for example, IT, professional services, transport, industrial products and services.

The supplier approach helps map sustainability issues related to each supplier across multiple contracts or geographical locations. In supply chain mapping, the company gathers information on suppliers and their suppliers to create a map of the global network. Implementing such information systems will help your organisation in the decision-making process.

A supplier approach helps understand the supply chain and takes into account:

- Where the most significant raw materials, goods and services come from;

- Where the labour is sourced from;

- How the goods are transported, reviews the suppliers’ historical performance;

- And, by whom.

In a sustainability issue approach, the company can map relevant issues to different categories of goods and services to assess the impact of the issue on the group. This should be done by involving key stakeholders involved in each sustainability issue.

.png?width=879&name=Figure%203.%20Examples%20of%20a%20sustainability%20issues%20approach%20(1).png)

Step 4 – At the reporting level

To ensure that the organization is meeting its sustainable procurement priorities, it should implement a performance measuring system. The system allows the company to establish a baseline measurement. From there, associated sustainability goals and KPIs can be tracked during the years.

Measurement can be qualitative or quantitative and can be applied to both procurement practices and outcomes. Measurement can be based on both metrics and indicators. Metrics are the raw data collected to understand performance, while indicators are used in decision making (i.e. metrics on the use of energy and source can be transformed into an indicator related to carbon emissions).

Reporting allows keeping track of the success of the activities and the KPIs associated. Reporting involved a large number of stakeholders both internally (e.g. the procurement team) and externally (e.g. the suppliers).

Below, are some examples of stakeholders involved in the reporting activities.

In order to reduce the burden of reporting, an organisation can do two things. First, identify a limited number of important indicators and metrics to communicate on important issues. Secondly, draw from internationally accepted sustainability reporting frameworks for sustainability metrics.

Conclusion

Implementing sustainable procurement means changing the way the company approaches the procurement process. It requires putting the well-being of the planet and the people first. Doing so will bring additional value to the company.

Sustainable procurement, if properly implemented, can result in many benefits. To name a few:

- An improved manufacturing process;

- Optimised inventory management;

- Process and product innovation;

- Strong supplier relationships;

- Improved sustainability performance.